BLACKSMITHS OF THE DISTRICT - PAST AND PRESENT.

based on material collected by DONALD SOLEY

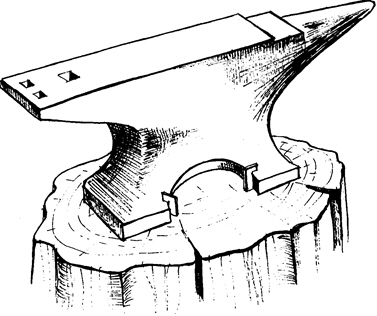

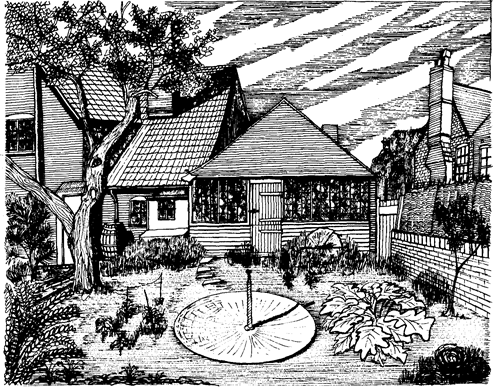

On Jubilee Day this year Miss E.L. Addison re-opened the Old Forge (see illustrations) which she has carefully preserved beside her house in Broad Street, established Peter Richardson the blacksmith in it and a forge was working there again. In 1953, to start the Coronation celebrations our Loyal Salute was given by the 'firing of anvils' in the Dean, organized by Tom Baker the blacksmith. He showed that a fine, hearty bang can be produced by compressing gunpowder in a hole on the anvil and igniting it with a fuse.

However, although the Hampshire Directory of 1859 showed 11 blacksmiths in the district — today the Yellow pages show only one! Before all knowledge of these rural craftsmen is lost, this paper records who some of them were, the conditions under which they worked and the lasting contribution they made to our heritage.

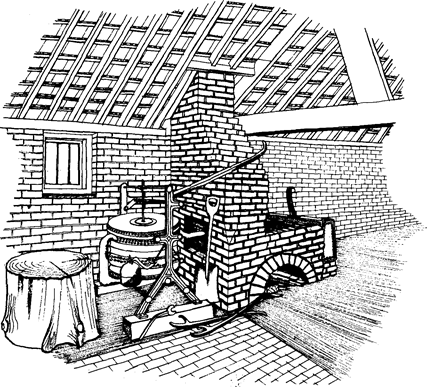

Today the nearest working forge to Alresford is that of Mr. Walter Murphy at Preston Candover. As his smithy is a fine example of at least 100 years of continuous use, it is worth describing in some detail. Set back some 30 yards from the highway, the premises are `L-shaped' in plan, each leg being 28 foot long and 14 foot wide. The walls are built of 14" brick above which are wooden rafters supporting a roof of clay tiles.

One of the two original forges remains, brick built with a brick chimney, having a 4'6" square hearth supported on steel bars. The hole beneath made a snug place for the blacksmith's dog. Part of the hearth is a brick 'sink' in which coke breeze fuel is kept; in days gone by it was 'Welsh steam nuts'. In a small niche is a box of silver sand, used to clean the fire before it was made white hot for welding by hammering metal together.

In front of the sink is a cast iron tank of water for quenching and cooling metal. This carries an iron rail along which tongs of varying sizes are hung. The steel anvil is pointed at one end for use when forming horseshoes. The walls are festooned with a bewildering variety of tools, while amongst the standing implements are a hand operated rotary die stock for cutting threads; a motor driven 'Denby' verticle spindle drill and wrought iron stands of varying heights upon which the horses hooves are rested as the smith finishes the fitting and `clenches' the nails. There is a power-driven hacksaw, a machine for bending flat iron and another for rolling the iron tyres of cartwheels.

Today, the blacksmith more often travels to his work with his portable forge and gear than has the work brought to him, but I did watch `Murph’ as he is known to his friends, make a horseshoe at his forge and as he worked, he talked about his trade:

"A shoe's made from a strip of metal. This one has a groove in it 'cause it's for a hunter. The biggest shoe I ever made was 9½" across. That was for a cart-horse and had a 'caulk' at the two ends, for the horse was flat-footed and needed this 'lift' to prevent it walking lame. Horses working on the land will go for two or three months without being re-shod but horses doing road work will be in again at less than half that time". He had re-heated the shoe and was hammering a pointed tool into the groove to make the nail holes. "A hoof, like the human nail, is growing all the time. When a horse is re-shod the hoof has to be cut. My horses are like doctors' patients, I remember their characteristics and can make them a set of shoes from memory. Some farriers will fix the shoes when cold but I prefer to fit a hot shoe. I reckon to get a better setting by burning it into position. These nails are of Swedish steel". He drove the nails through the shoe and into the hoof, 'clenched' and filed them into a neat finish. "Never drive a nail into a previous hole," he warned. "Most horses are docile enough but you can get a difficult sod and then you've got to show who's master!"

I left `Murph' convinced that he was master of his craft as well as of the horse.

The most famous horse to be shod in the district was 'Cloister' of Bishop's Sutton, who won the Grand National in 1893. It is a sad fact that Mr. Padwick, the Sutton blacksmith at that time, died while this article was in preparation having lived a hundred years.

Children blessed blacksmiths for not only was the forge a lovely, warm, noisy, smelly place but it also produced hoops - and bowling hoops was a grand village game right up to the 1930's. Mr. Benham of Old Alresford remembers his hoop being made by the local smith, complete with its 'skimmer', the metal hook by which the hoop was guided and driven. Mr. Norgate of Itchen Stoke remembers the hoop made for him by Bill Giles, while Bert Brown of Martyr Worthy has given us this first hand memory of Mr. Giles and his skill:

"The old blacksmith's shop at Itchen Stoke was in the dead end lane, known as Wixons. It was a timber building with a tiled roof — very dark inside except for the two forges for there was very little in the way of windows, just some wooden shutters and the half-doors that were always open. Bert Giles was the blacksmith and what a craftsman he was! He could repair anything from a traction engine to a clock and he could make most things. The only tools he ever bought were saws and files. I believe he made the Bishop of Winchester a Crook, and he certainly helped Bert Love make the church gates at Bighton. He was well known as a locksmith and was particularly skilled at tempering steel. He could make the springs for the old rat and rabbit gin traps and did it all on the forge fire. It was in the blood, his father had a foundry at Ovington."

"Bill married a girl from Barton Stacey and used to walk there from Itchen Stoke every Sunday to do his courting, for although he repaired cycles for other people, he'd never learnt to ride one himself. I don't think he did any shoeing but he rented a building from Manor Farm, which he used for repairing the bigger farm machinery such as reapers and binders."

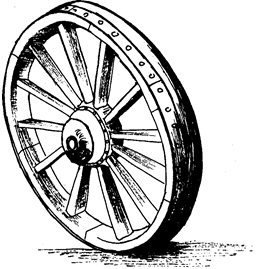

Mention of farm machinery is a reminder of the blacksmith's association with wheel-wrights. Isabel Sanderson in her second book on 'Dwellings in Alresford' draws attention to the large disc made of iron about 1" thick and some 5 feet in diameter which is in the garden behind the old smithy at No. 44 Broad Street. This disc was in use when iron rims were fitted to wooden cartwheels which had been brought to the blacksmith by the wheel-wright. Mr. A.H. White of Alresford describes watching this process as a child about 1910 at the smithy in the Dean run by Tom Hounsham and his son.

"I used to love to go with my father to watch the blacksmith fit the iron tyres to cartwheels. This consisted of measuring the outer edge of the wheel felloes with a small metal wheel; then a length of strip iron was bent, measured and shut together. This was then placed on bricks on the ground and faggots of wood heaped on the tyre, and kept alight until the tyre was red hot. Meantime the wheel was secured to a round metal disc by a screw in the centre - again on the ground. When it was judged that the heat of the tyre was correct it was placed on the wheel and quickly knocked on with sledge hammers. Other men were standing by so that immediately the tyre was fully on, cans of water were applied to shrink the tyre onto the wheel. This had the effect of tightening all the wood joints with the result that one had a very firm wheel".

Blacksmiths have been required by the community since the beginning of time, so that often the smithy is the oldest standing building in the village other than the church. As they are places where work has been continuous they have been very little altered over the years, which accounts for their ramshackle appearance in many cases. Sometimes a foundry was attached to the smithy as is the case at the property owned by Mrs Randall at Old Alresford. Here the smith went by the brave name of `Rampton - Blacksmith and Iron-Founder' and it is hoped to make the property the subject of a separate paper.

In the case of New Alresford, the fire of 1689 was so destructive that it is only possible to date the blacksmith's shop in Broad Street from 1701 when the property came into possession of connections of the Keen family, who were long established smiths. From that date the building has been maintained as a smithy with its correct gear so that, as has already been described, it could be re-opened 'at the drop of a hat' by the present owner for the Jubilee.

So ancient is the blacksmith's trade that at gatherings of the guild on November 23rd - St Clements Day - the reading of the tale of King Solomon and the blacksmiths has a set place in the order of ceremony. However we, in the heart of Wessex, will settle for the legend of King Alfred and his smith:

"The king wished to decide who was the 'father of all craftsmen' so he gave a banquet which they all attended bringing a specimen of their work. Everyone had done a good job, so to avoid jealousy King Alfred gave the title to his tailor, who had brought a coat of `surpassing beauty and exquisite fashion'.

"The blacksmith was angry at this and didn't return to his forge after the banquet, with the result that the mason couldn't get new tools, the carpenter was without chisels, the hinges of the gates were not mended, the king's horses couldn't be shod, the tailor's scissors couldn't be repaired and the warriors could not fight with their weapons in bad repair. So King Alfred and all the craftsmen broke into the smithy and tried to do the work themselves. But they failed and the scene in the smithy became one of chaos and confusion."

"Then who should walk in but St Clement with the blacksmith beside him, the latter very angry at the wreckage of his forge. St Clement out-stared the king until the latter, making a humble bow to the Saint, declared 'I have made a great mistake in allowing my judgement to be governed by the gaudy colour and stylish cut of the tailor's coat. In justice to the blacksmith, without whom none of us can do, I proclaim him father of all craftsmen'. Then the king held another banquet at which the blacksmith was guest of honour and entertained the company with the song `Twankydillo' and as he sang the spiteful tailor crept under the table and snipped pieces out of the blacksmith's apron — which is why today the smith's apron has a fringe."

One final fact about the trade of blacksmith. St Martin, the patron saint of those who travel on horseback has a horseshoe as his emblem. In the Middle ages, many a traveller facing a long journey would ask the smith to forge an extra shoe to hang at home to ensure the protection of St Martin. So now you know why there's a horseshoe on your door!.